The seafood canning involves the combination of packaging in hermetically sealed containers and a heat treatment to ensure commercial sterility.

The conservation of fish in Morocco goes back to several centuries. According to some historians, the first sardine canning factories appeared during the First World War.

Thanks to the improvement of manufacturing technologies, to wealth of Moroccan waters in fish, notably the Sardina Pilchardus Walbaum and to the innovation and diversification of products, this activity has known a great development over the years.

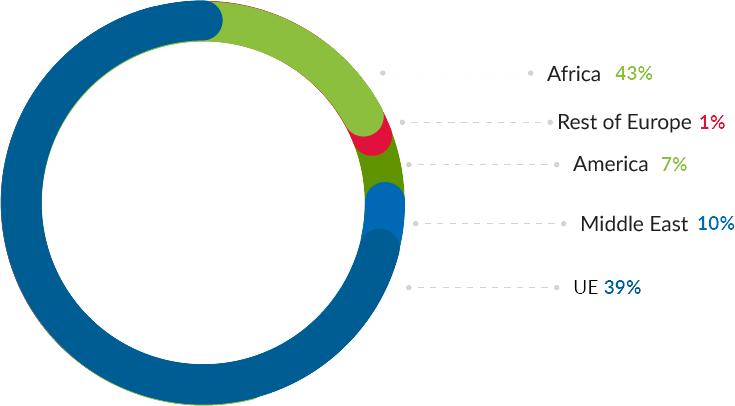

That is how the Moroccan fish canning was able to conquer several international markets and positioned Morocco as the world's leading exporter of canned sardines.

Statistic data

The production of canned fish relates to 44 units located mainly in Safi (20) and Agadir (12). In 2012, these units produced 152.225 tons of canned fish.

The cans export of all products combined resulted to 4,294 million Dhs mainly directed to the African, European and Middle East markets.

Main export destinations of Moroccan preserves in values

Canned pelagic production

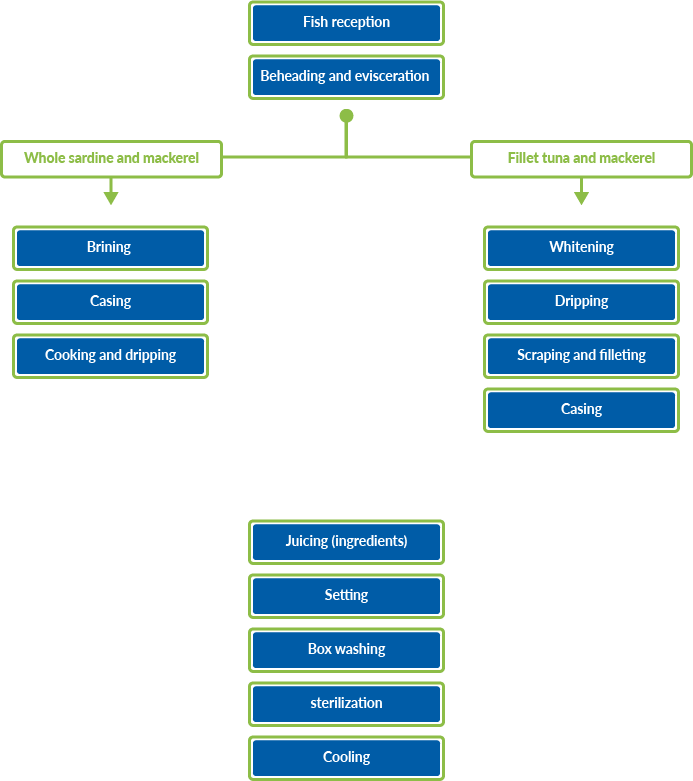

The reception is a critical step in the manufacturing process, the product must be accompanied by a health certificate and traceability documents and must be transported in means complying with the regulations on transport hygiene. The control reception concerns also the temperature, the organoleptic quality and the chemical analysis of the fish.

beheading, tailing and evisceration are manual operations performed by highly qualified women. These cut the head and tail of the fish either manually or with stainless steel scissors. The viscera are removed manually without damaging the integrity of the flesh. All these operations must be done quickly to avoid the alteration of the fish.

Brining consists of immersing the fish in the basins of the line containing brine, the purpose of which is to rid the fish of its blood, improve the taste and facilitate the stain of the workers placed on the other side of the line for the casing. The concentration of the brine depends on the mold, the type of fish and the customer's request.

The casing is a very important step which must be well controlled to not to exceed the capacity of the box and thus to avoid a bad crimping, to have a good juicing and to gain the trust of the customer (weight indicated).

The purpose of steam-cooking is to coagulate fish protein and increase its firmness by partial dehydration, to increase the nutritional value, to enhance the taste, to drain the product and to facilitate the release of blood and fat to avoid the fish remaining waterlogged and too soft before sterilization.

For tuna and mackerel, a whitening and dripping operation precedes filleting and canning. The whitening is done in boiled brine at 100 ° C, it has the same objectives as steam-cooking, but it gives a better organoleptic quality (smell, flavor, texture and taste).

Beheading, tailing and evisceration are manual operations performed by highly qualified women. These cut the head and tail of the fish either manually or with stainless steel scissors. The viscera are removed manually without damaging the integrity of the flesh. All these operations must be done quickly to avoid the alteration of the fish.

Scraping and filleting involves manually scraping the skin of the bleached fish and dividing it in half to remove the bones and blood, and cut into fillets. This step must be done quickly and properly to fit the shape of the box and avoid any alteration of the product. A visual control is made to check the presentation of the filled box, the color of the flesh and the absence of skin, blood and inedible parts.

Juicing consists of adding vegetable oil, olive oil or tomato sauce, with or without ingredients. Before adding juice all the boxes are systematically checked visually.

Setting is a critical step in the manufacturing process. Its purpose is to pack the product in a waterproof box, gas-tight and micro-organisms. Seam quality control is essential for the preservation of the product (visual inspection, dehulling control and graph control).

Sterilization is a very critical step which consists of subjecting the cans to a thermal treatment sufficiently intense to destroy or inactivate all the microorganisms and enzymes likely to alter the product or make it unfit for consumption. Several controls are necessary during this step namely, the control of the sterilization scale, the sterilization cycle and the microbiological and organoleptic incubation tests.

Box cooling and drying them is a critical step because it is estimated that temperatures above 40 ° C influence the tightness of the metal. It is strictly forbidden to touch the boxes before the end of this stage.